Printing machine operators, also known as press operators, prepare, operate, and maintain printing presses. Duties vary according to the type of press they operate. Traditional printing methods, such as offset lithography, gravure, flexography, and letterpress, use a plate or roller that carries the final image that is to be printed and copies the image to paper. In addition to the traditional printing processes, plateless or nonimpact processes are coming into general use. Plateless processes—including digital, electrostatic, and ink-jet printing—are used for copying, duplicating, and document and specialty printing, usually by quick printing shops and smaller in-house printing shops. Digital presses with longer run capabilities are increasingly being used by commercial printers for short-run or customized printing jobs. Digital presses also allow printers to transfer files, blend colors, and proof images electronically, thus avoiding the costly and time-consuming steps of making printing plates that are common to lithographic or off-set printing.

Printing machine operators' jobs differ from one shop to another because of differences in the types and sizes of presses. Small commercial shops with relatively small presses, those that print only one or two colors at a time, can be operated by one person, often an owner or manager who performs all business activities. To attract a wider range of clients, larger commercial print shops may run several presses with different size and color capacities. Press operators typically specialize in operating one type of press but may operate more than one press at a time. However, press operators who are trained on more than one type of printing press are valuable because they can work on multiple types of printing jobs. Large newspaper, magazine, and book printers use giant “in-line web” presses that require a crew of several press operators and press assistants.

After working with prepress technicians to identify and resolve any potential problems with a job, press operators prepare machines for printing. To prepare presses, operators install the printing plate with the images to be printed and adjust the pressure at which the machine prints. They then ink the presses, load paper, and adjust the press to the paper size. Operators ensure that paper and ink meet specifications, and adjust the flow of ink to the inking rollers accordingly. They then feed paper through the press cylinders and adjust feed and tension controls. New digital technology, in contrast, is able to automate much of this work.

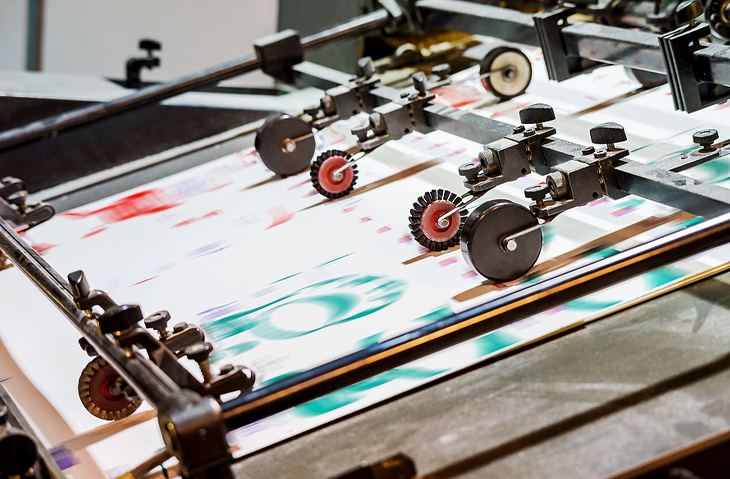

While printing presses are running, press operators monitor their operation and keep the paper feeders well stocked. They make adjustments to manage ink distribution, speed, and temperature in the drying chamber, if the press has one. If paper tears or jams and the press stops, which can happen with some offset presses, operators quickly correct the problem to minimize downtime. Similarly, operators working with other high-speed presses constantly look for problems, and when necessary make quick corrections to avoid expensive losses of paper and ink. Throughout the run, operators must regularly pull sheets to check for any printing imperfections. Most printers have, or will soon have, presses with computers and sophisticated instruments to control press operations, making it possible to complete printing jobs in less time. With this equipment, press operators set up, monitor, and adjust the printing process on a control panel or computer monitor, which allows them to control the press electronically.

In most shops, press operators also perform preventive maintenance. They oil and clean the presses and make minor repairs.

Work Environment

Operating a press can be physically and mentally demanding, and sometimes tedious. Press operators are on their feet most of the time. Operators often work under pressure to meet deadlines. Most printing presses are capable of high printing speeds, and adjustments must be made quickly to avoid waste. Pressrooms are noisy, and workers in certain areas wear ear protection. Working with press machinery can be hazardous, but the threat of serious accidents has decreased. Newer computerized presses are equipped with safety features and allow operators to make most adjustments from a control panel. Many press operators, particularly those who work for newspapers, work weekends, nights, and holidays as many presses operate continuously. They also may work overtime to meet deadlines. Most operators worked 40 hours per week.

Education & Training Required

Beginning press operators load, unload, and clean presses. With time and training, they may become fully qualified to operate that type of press. Operators can gain experience on more than one kind of printing press during the course of their career.

Experienced operators will periodically receive retraining and skill updating. For example, printing plants that change from sheet-fed offset presses to digital presses have to retrain the entire press crew because skill requirements for the two types of presses are different.

Apprenticeships for press operators, once the dominant method for preparing for this occupation, are becoming less prevalent. When they are offered by the employer, they include on-the-job instruction and related classroom training or correspondence school courses.

Formal postsecondary programs in printing equipment operation offered by technical and trade schools, community colleges, and universities are growing in importance. Postsecondary courses in printing provide the theoretical and technical knowledge needed to operate advanced equipment. Some postsecondary school programs require two years of study and award an associate degree.

Because of technical developments in the printing industry, courses in chemistry, electronics, color theory, and physics are helpful.

Other Skills Required

Persons who wish to become press operators need mechanical aptitude to make press adjustments and repairs. Workers need good vision and attention to detail to locate and fix problems with print jobs. Oral and written communication skills also are required. Operators should possess the mathematical skills necessary to compute percentages, weights, and measures, and to calculate the amount of ink and paper needed to do a job. Operators now also need basic computer skills to work with newer printing presses.

How to Advance

As press operators gain experience, they may advance in pay and responsibility by working on more complex printing presses. For example, operators who have demonstrated their ability to work with one-color sheet-fed presses may be trained to operate four-color sheet-fed presses. Voluntarily earning formal certification may also help press operators advance. Operators also may advance to pressroom supervisors and become responsible for an entire press crew. In addition, press operators can draw on their knowledge of press operations to become cost estimators, providing estimates of printing jobs to potential customers, sales representatives, and instructors of printing-related courses, or move into other administrative or executive occupations.

Job Outlook

Employment of printing machine operators is projected to decline moderately, as newer printing presses require fewer operators. Despite this, job opportunities are expected to be favorable because a large number of these workers are expected to retire or leave the occupation over the next decade. The best opportunities will be available to skilled press operators.

Earnings

Median hourly wages of printing machine operators are $25.46, compared to $23.99 per hour for all production occupations. The middle 50 percent earned between $16.65 and $30.08 an hour. The lowest 10 percent earned less than $19.13, and the highest 10 percent earned more than $29.98 an hour.

Median hourly wages are $27.70 in newspaper, periodical, book and directory publishers and $25.85 in printing and related support activities, industries employing among the largest numbers of printing machine operators.

The basic wage rate for a printing machine operator depends on the geographic area in which the work is located and on the size and complexity of the printing press being operated.